Plastic Omnium is a leading Tier 1 supplier to the global automotive industry. BasePower has developed and installed a Combined Cooling, Heat and Power ('Trigeneration') project at its facility in Measham, Derbyshire.

The Energy Challenge for Automotive Manufacturers

Plastic Omnium is a world leader in the design and manufacture of bumpers, fenders, body panels and body modules, serving 15% of the global market for exterior components. The company’s plant in Measham, Derbyshire is a Tier 1 supplier to JLR, Nissan and other automotive manufacturers throughout the UK.

The automotive industry operates in a tough competitive environment, characterised by high-energy use and strong buyer power, meaning that input cost rises are very hard to pass on. Determined to manage costs and carbon emissions in an uncertain economic environment, Plastic Omnium turned to BasePower to develop an on-site power generation project that would reduce both its energy consumption and CO2 footprint.

An Energy Partnership

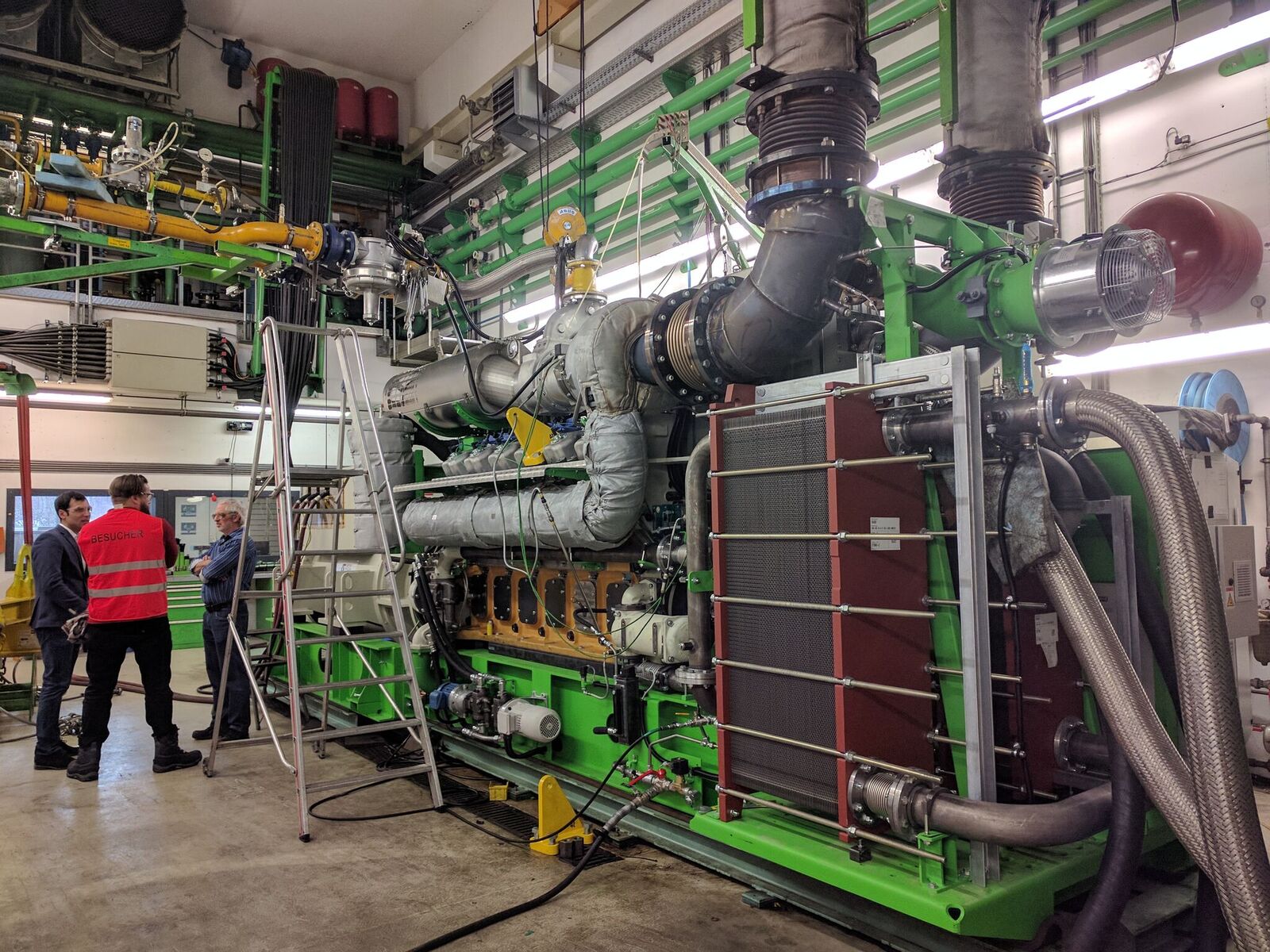

Plastic Omnium attend the CHP Engine test

Plastic Omnium and BasePower worked in partnership for over a year to create a trigeneration project that would best serve the needs of the high-volume manufacturing facility. A project agreement was signed In June 2016 to install a Combined Cooling, Heat and Power (Trigeneration) scheme at their manufacturing site in Measham, Derbyshire.

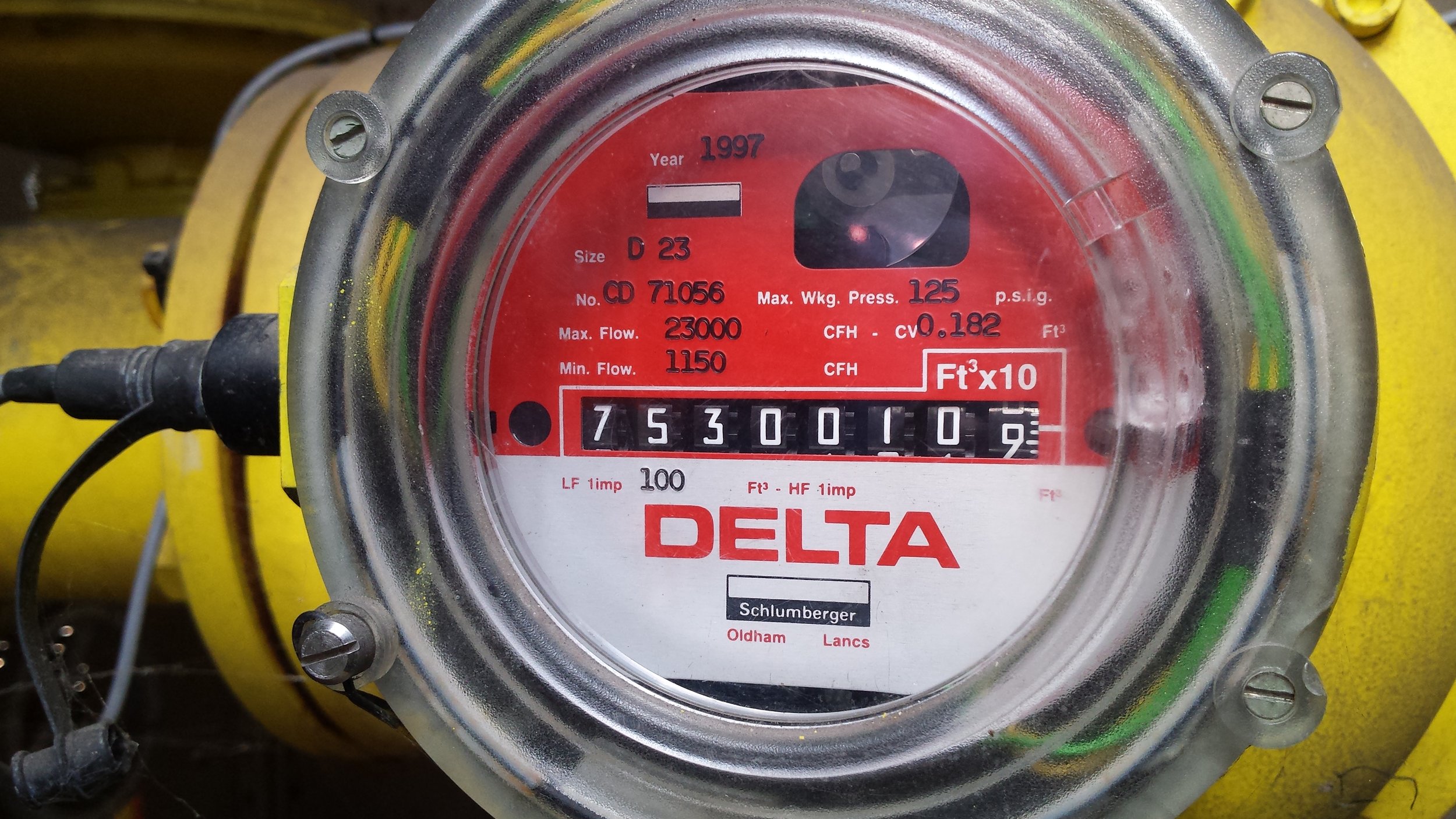

The on-site CHP scheme supplies 2MW of power for use in the high-volume manufacture of injection mouldings and exterior automotive assemblies.

During the cooler months the heat by product from the power generation process is used to maintain accurate temperatures at critical locations in the plant, including the paint shop. As heat demand reduces in warmer weather an integrated Absorption Chiller turns surplus heat into chill to offset cooling loads.

Developed and fully financed by BasePower, a fully containerised CCHP system has been installed on the Measham site.

Operational and Strategic Benefits

"Another benefit was no capital investment; this was all part of the BasePower deal which was a big upside for us a business."

Mark Perrins, Site Director, Plastic Omnium Measham

The project at Plastic Omnium is providing substantial savings on energy that would otherwise have been supplied from the electrical and gas grids, and has reduced peak summer cooling demand. A reduction of 250 tonnes in CO2 emissions was also achieved in the first full year of the scheme’s operation.

Mark Perrins, Site Director at Plastic Omnium Measham said:

"We have achieved and exceeded the targeted savings for electricity usage and heat so that has been great. Another benefit was no capital investment; this was all part of the BasePower deal which was a big upside for us as a business. Our CO2 footprint has also been considerably improved through the project.”

BasePower on-site energy schemes have since been rolled out at other Plastic Omnium UK sites including Hams Hall and Warrington. We continue to build on a close liaison to identify opportunities for heat infrastructure refurbishment, to further enhance efficiency and carbon savings.